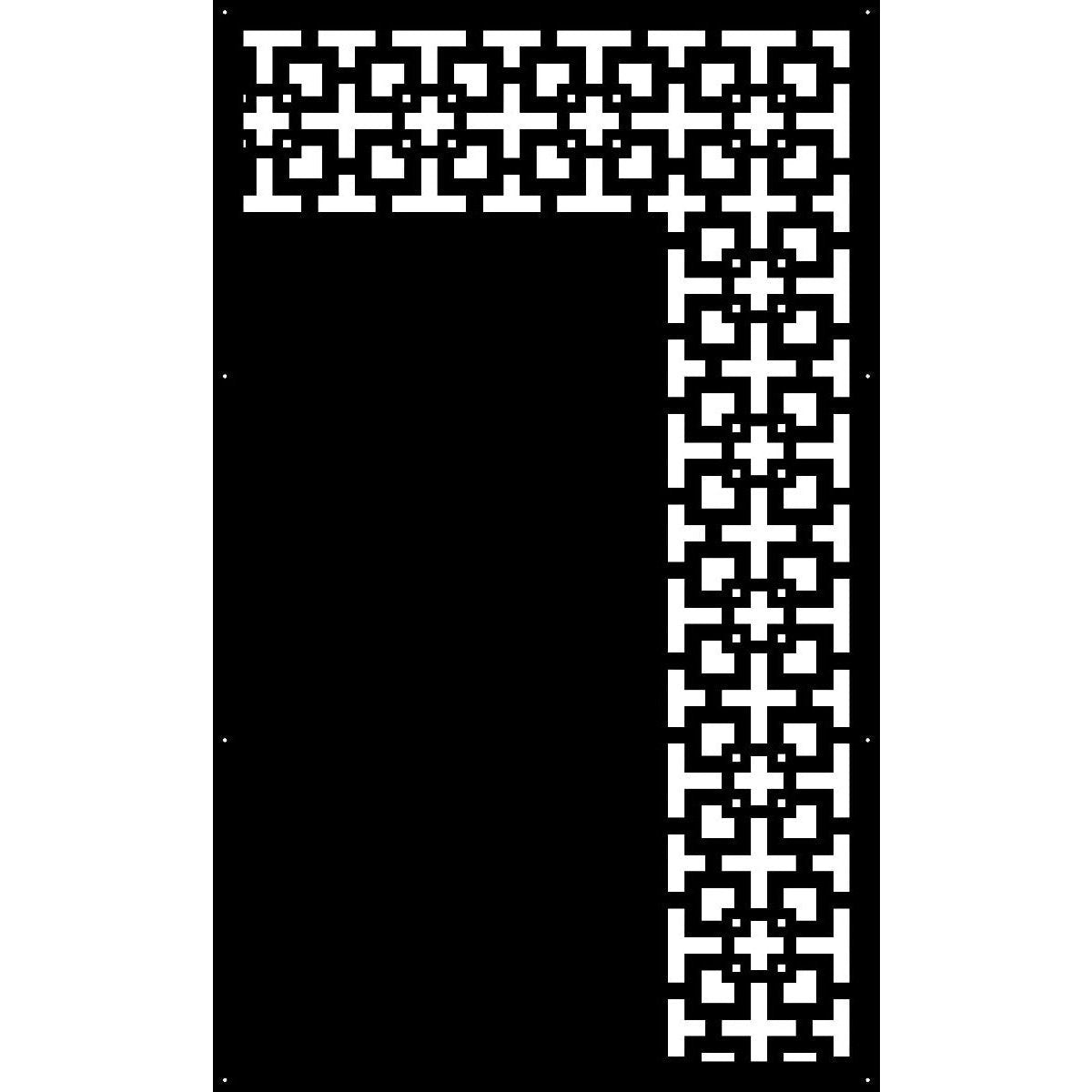

Combination Fence Panel - Square in Square

New Zealand Made – Laser Cut Outdoor Privacy Screen & Fence Panels.

“ Squares N Squares”. This combination panel set is ideal for long fences spans that may otherwise look repetitive.

Another one from our "MetalMosaic " range designed to provide high level of privacy without blocking your view fully.

Benefits of our "MetalMosaic" laser cut fence panels & privacy screens.

- Balanced privacy and views – create a boundary fence or a private outdoor area around your spa. This range of panels have just enough cut outs so your view is not totally blocked.

- Shade – We love our summer but it is always nice to find a bit of shade. A privacy screen can offer this much-needed shade and reduce wind gusts to provide some level of wind protection.

- Hiding eyesores – Things like air conditioning units and rubbish bins can be really distracting. Privacy screens are a good way of dividing and keeping these out of sight.

- Low Maintenance : Both corten steel and powder coated architectural panels need minimum to no looking after. Gently hose them down occasionally to get rid of dust and salt in the coastal areas and they will last decades.

Dimensions :

Panel Size : 1800 x 1100 mm, 1500 x 1100 mm

Thickness : 3.00 mm / Corten / Aluminium

Please note that Corten steel products are supplied in a bare metal, raw untouched finish, and will develop a rusty patina in a few weeks, giving it a beautiful and natural look.

The powder coated products are made in aluminium and are suitable for indoor and outdoor use.

Dispatch time : We aim to dispatch corten steel panels within 2 weeks and powder coated panels in 3 weeks of the order/purchase.

Can these be altered to fit my existing space?

These panels are made to order and we can alter the design and size to suit your requirements. Please reach out to us for your size and design variation requirements.

Can I install the fence panels and screens myself?

We recommend that these privacy screens be installed by a qualified tradesperson. However, if you are good with a measuring tape and can handle a drill/driver, you will have no issues installing the panels. Please check our install guide for details about post installs.

Why choose our Laser Cut Panels

Our fence panels and privacy screens don’t just fill spaces, they start a conversation. They are a creative way making your house stand out.

Our privacy screens are designed and manufactured in New Zealand on high definition laser cutters ensuring very smooth edges and clean designs. We use locally precured materials where ever possible. By choosing our products you are also supporting the Kiwi industry.

In addition to the fence panels we can also supply

- Custom Brackets

- Metal posts

- Framework

- Mounting pins ( welded behind the panels )

- Stainless Steel spacers

Contact us for a custom quote

Contact form

- Choosing a selection results in a full page refresh.

- Opens in a new window.